Main Projects

- Technical assistance for transferring used rolling stock to railway operators in Indonesia

- MRT Purple Line

- Indian High-Speed Rail Project

- International Standardization

Technical assistance for transferring used rolling stock to railway operators in Indonesia

Jakarta, the capital of Indonesia, which has experienced severe traffic congestion, has seen improvements in its public transportation. The existing railways also require urgent increase transportation capacity expansion. Therefore, since 2013, JR East has transferred a total of 812 used Series 205 cars to PT Kereta Commuter Indonesia (PT KCI). These cars now serve as the major and essential rolling stock for the commuter rail service in the Jakarta metropolitan region. Taking advantage of this first opportunity, JR East concluded a memorandum of understanding (MoU) with PT KCI and its parent company, PT Kereta Api Indonesia (PT KAI).

We continue to offer not only technical support for rolling stock maintenance, but also various training programs for PT KAI and PT KCI. The training programs include improving the quality of hospitality and service, ground equipment maintenance, train crew management and safety, which enhanced the skills of about 100 trainees in 2023. JR East group companies also supply high-quality consumable and wearable parts for rolling stock and other railway materials to support the stability and safety of the railways in Indonesia.

MRT Purple Line

JR East is participating in a project to provide total maintenance services for train cars and various ground facilities on the MRT Purple Line, an urban railway in Bangkok, Thailand. The Purple Line started its operation in August 2016, connecting the northern district of Bang Sue with the northwestern suburb of Bang Yai in Bangkok. We cofounded Japan Transportation Technology (Thailand) Co., Ltd. (JTT) in Bangkok, together with other Japanese corporations, for train cars and ground equipment maintenance of the Purple Line.

Train cars were manufactured by Japan Transport Engineering Company (J-TREC), one of our group companies. This marks the first case of Japan-made train cars supplied for Bangkok metropolitan transportation, and a business consortium, including railway operators, participated in the railway maintenance business. JR East employees are seconded to JTT for business administration and technical guidance to optimize maintenance, contributing to highly reliable train operations.

About JTT

Left :

Kaviphat NUTTAVUTHISIT (Ike)

Project Director

Japan Transportation Technology (Thailand) Co., Ltd (JTT).

Kaviphat NUTTAVUTHISIT is the Head of the Technical Division and worked as a consultant for JTT since June 2015, prior to the opening of the MRT Purple Line. He grew up in Thailand and graduated with a master's degree in mechanical engineer in Germany, he worked for SIEMENS, where he gained extensive knowledge of the MRT Blue Line and a deep understanding of Thailand's Railway-related affairs. His original expertise is in rolling stock.

Right :

Yoshihisa MITOMA

Deputy Project Director

Japan Transportation Technology (Thailand) Co., Ltd (JTT).

Yoshihisa MITOMA is the Deputy Head of the Technical Division. He has amassed experience in both the construction division for planning, design, and supervision and in the maintenance division for planning and on-site operations of various projects. His original expertise is in power supply systems and prior to the opening of the MRT Purple Line, he served as a power supply system engineer for the Purple Line’s engineering, procurement and construction (EPC) from 2013 to 2016.

Past Efforts and Future Prospects

JTT was established in December 2013 through investments from Marubeni, Toshiba, and JR East with the primary objective to provide comprehensive maintenance services for the MRT Purple Line in Bangkok, overseeing four key departments: Rolling Stock, Depot Equipment, Power Supply, and Track Work.

At JTT, safety is our top priority. JTT actively promotes safety awareness through regular safety meetings, training programs, safety patrols including Safety and Quality Audits, and risk analysis. All maintenance activities are meticulously planned and executed based on manuals, work instructions, and checklists to ensure reliability and consistency. By maintaining the highest quality standards, JTT delivers safe, reliable, and comfortable transportation services to our customers.

Our efforts have yielded remarkable results. According to statistical data published by the Department of Rail Transport of Thailand (DRT), the Purple Line has recorded the fewest train service interruptions among all railways in Thailand for three consecutive years: 2021 to 2023. Notably, in 2023, 121 train service failures occurred overall, but the Purple Line recorded zero, which continues as of the end of December 2024.

This is significantly attributed to the successful transfer of expertise and best practices from JR East to JTT. The following initiatives are examples of the knowledge and know-how integrated into our maintenance work:

- 5S Activities: Principles of work environment improvement derived from the Japanese workplace motto words, seiri (sort), seiton (set-in-order), seiso (shine), seiketsu (standardize), and shitsuke (sustain the discipline).

- Pointing and Calling: A method in occupational safety to avoid mistakes by pointing at important indicators and verbally calling out their status.

- KYT: Kiken Yochi Training (Hazard Prediction Training) is an activity that involves practicing measures to notice hazards and unsafe conditions in actions and environments.

- Lesson Learn Calendar: A calendar to prevent similar accidents from occurring by compiling past troubles into documents and reviewing them daily to alert workers.

JTT remains committed to delivering world-class maintenance services by utilizing JR East's expertise and continuously improving our processes to ensure customer’s safety, reliability, and satisfaction.

Indian High-Speed Rail Project

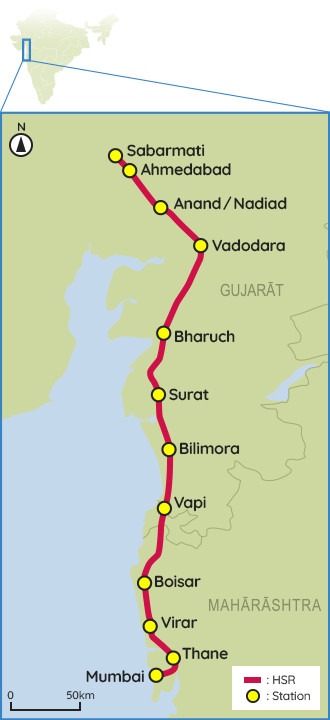

- 【Overview of the MAHSR Project】

-

- Number of Stations planned:

- 12 stations

- Distance:

- 508 km

- Travel time:

- About 2 hours

- Operational speed:

- 320 km/h

At the India-Japan Summit in December 2015, the Mumbai-Ahmedabad High Speed Rail (MAHSR) project was confirmed to develop using Japanese HSR technology, specifically, the Shinkansen System, and experience.

As a Shinkansen-operation company with experience and knowledge, JR East was requested by the Japanese government—more specifically Ministry of Land, Infrastructure, Transport and Tourism, and Japan International Cooperation Agency (JICA)—to support the Japanese government’s steady implementation of the Shinkansen System in the MAHSR project. In addition to the participation in meetings between the two governments, JR East supports Japan International Consultants for Transportation Co., Ltd. (JIC), which has been working on the design and tender support, and construction supervision; Japan Railway Technical Service (JARTS), which educates and certifies Indian engineers and technicians in the field of the track construction; and Japan High Speed Rail Electric Engineering Co., Ltd. (JE), which handles work on behalf of National High Speed Rail Corporation Limited (NHSRCL) in the field of electrical systems.

In the MAHSR project, JR East supports not only the technical aspect of the HSR facilities, but also the human resource development for members of NHSRCL, which is a construction and business entity of the MAHSR project. JR East, its group companies and other companies related to the Shinkansen operation have provided training, conducted lectures, and facilitated observations. From July 2017 to November 2018, training programs for about 30 executive and department head level members of NHSRCL were implemented, divided in three sessions of 2 weeks each. From April to June 2022, Training for Key Operation and Maintenance (O&M) Leaders (KOMLs) who are NHSRCL’s 13 engineers of five divisions—transportation, rolling stock, facility (track and civil), electrical, and signal & telecommunication —was conducted in Japan. These leaders are responsible for proposing and carrying out practical O&M activities in NHSRCL. JR East, its group companies, and other companies related to the Shinkansen operation provided a systematic and comprehensive overview of O&M of the Japanese Shinkansen System to KOMLs.

In addition, from August 2023 to April 2024, an OJT program, which provided more practical training, was implemented for KOMLs, the same members who participated in the Training in 2022. For these training programs, experts from each technical field in JR East accompanied and supported the trainees’ learning through lectures, observations and other activities.

(Rolling Stock Division)

JR East Group's Initiatives

- Japan International Consultants for Transportation Co., Ltd. (JIC)

- JIC established a consortium with Nippon Koei Co., Ltd. and Oriental Consultants Global Co., Ltd. The consortium, Japan International Consultants Consortium (JICC) awarded a contract for General Consultancy (Excluding Supervision) of the Mumbai – Ahmedabad High-Speed Rail Project (Technical Support by JICA Grant aid), including preparing design and tender documents, and tender support services to NHSRCL. All civil work packages have started construction until August 2023.

Furthermore, in 2022, JICC received a contract from NHSRCL for Construction Supervision Services related to the tracks, rolling stock, rolling stock depots, maintenance vehicles, and operation training simulators. Currently, members of JICC are working in India.

International Standardization

JR East has been committed to enhancing the advantages of railways globally as an environmentally friendly mode of mobility. In collaboration with national governments and related organizations, we are actively engaged in standardization activities. We participate in developing international standards related to railways, such as those issued by ISO, IEC, and UIC’s industry standards (IRS) , to gain insights into global railway technologies and share Japan’s expertise in rule-making activities with the world.

For example, we have contributed to developing ISO 22083, which ensures safe railway operations during natural disasters through reliable and swift operational restriction and resumption. We have also participated in developing ISO 24675, which enables stable transportation through accurate scheduling, and ISO 23019, which facilitates efficient and practical training for drivers. These efforts contribute to advancing the global railway industry.

Moving forward, we will continue our commitment to international standardization, showcasing Japan’s excellent railway technologies and contributing to technological innovation in the global railway industry.

- ISO 22083:

- Concepts and basic requirements for the planning of railway operation in the events of predictable natural hazards

- ISO 24675:

- Running time calculation for timetabling

- ISO 23019:

- Driving simulator for drivers‘ training