Press Releases(Archive)

Progress in Measures to Prevent Shinkansen Derailment

East Japan Railway Company

October 20, 2006

Two years have passed since the derailment of Joetsu Shinkansen Toki No. 325 during the Niigata Chuetsu Earthquake on October 23rd, 2004. Measures that were adopted in the aftermath of the earthquake and the progress we made in our investigations into methods of preventing derailments were announced in October of last year, and we have been continuing with these measures ever since. We have now begun implementing newly developed measures based on the knowledge gained through these investigations in addition to policies that have been adopted to date, and this press release is to provide details on these projects and the progress we have made so far.

1. Measures for which Adoption has Commenced

We are currently proceeding with the adoption of anti-derailment measures in accordance with the chart shown below.

2. Measures under Development

We are continuing with the development of anti-toppling devices to be fitted onto railway tracks and are currently carrying out strength tests on prototypes, with plans for installation. We have constructed a simulation model based on the results of these tests, and the outcome of various analyses has enabled us to come very close to achieving actual rail anti-toppling devices.

3. Large-Scale Earthquake-resistance Measures Currently Underway

- Changes in methods for estimating earthquake scale, etc., were completed at the end of September 2006 with regard to improvements to the Shinkansen Early Earthquake Detection System. The addition of a function for stopping power transmission over the range affected by an earthquake will also be implemented by the end of October 2006. The increased installation of wayside seismometers (28 locations) is also expected to be completed by the end of fiscal 2006.

- Local surveys into aseismatic countermeasures for Shinkansen tunnels that intersect active faults have been completed, and plans for these measures are currently being formulated.

[Reference]

1. Measures for which Adoption has Commenced

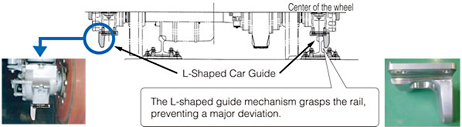

| (1) | L-Shaped Car Guides [Overview] |

This measure is designed to prevent the car from deviating too far from the rails in the event of a derailment. An L-shaped train guiding mechanism is installed on the bogie, and this mechanism prevents the wheels from moving sideways more than a set amount if the car derails.  [Level of Progress] Favorable results were obtained when confirming strength levels through tests and analyses, and this mechanism is currently attached to operating trains for verification purposes. The guiding mechanism is scheduled to be attached to all Shinkansen trains from January 2007. |

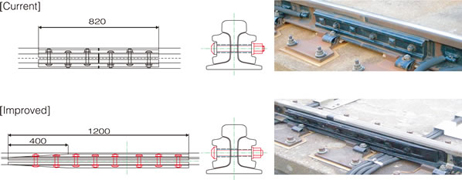

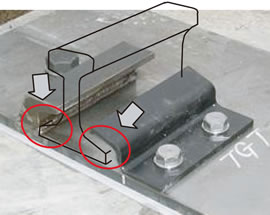

| (2) | Measures to Prevent Rail Breakage of Glued Insulated Joints [Overview] |

This measure is designed to reduce the shock applied to the glued insulated joints (metal fittings that join rails together at branches in the signal circuit) when wheel or bogie parts come into contact with them during derailments. In more detail, the shape of the joints has been improved so that the wheel does not come into direct contact with the bolts on these joints.  [Level of Progress] Various prototype styles were created, and the results of strength and performance tests led to the shape and dimensions shown above being decided upon. Installation tests were then carried out on operating lines from February 2006, which verified that no problems with regard to installation or functionality existed. We are currently continuing with these installation tests on curves and ballast-track sections of operating lines. Having examined the results of these tests, installation in scheduled to commence on all areas (1,716 locations) from the end of fiscal 2006. |

| (3) |

Measures to Shorten Stop Distances [Overview] |

When the seismometers installed along the Shinkansen lines detect earthquakes, power to the overhead cables is suspended and the train stops. The train stopping method that has been used to date consists of the on-board ATC device detecting the fact that no power is flowing through the overhead wires and consequently the emergency brake is applied. We have now installed new devices for detecting power cuts, however, which has shortened the amount of time required to apply the emergency brake by approximately one second.  [Level of Progress] Examining the results of the basic data collected by the FASTECH360S (Shinkansen speed testing train) indicated good prospects for practical use, and we are currently verifying the situation with operating trains. These improvements are scheduled to be adopted by the entire Shinkansen fleet (132 trains) from November 2006. |

2. Measures under Development

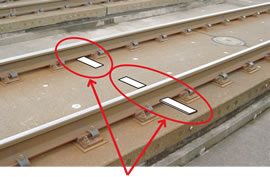

Rail Anti-toppling Devices

[Overview]

These devices prevent rails from toppling over or experiencing large lateral movement, even if the metal fastening joints that fasten the rails together (rail and sleeper fasteners) break during a derailment. This enables the rails to continue guiding the wheels of the rolling stock to keep the cars on the track.

(Prototype)

Rail anti-toppling device installed at base of rail prevents the rail from toppling over.

(Installation Image when Installed on Current Slab Tracks)

Installed between rail and sleeper fasteners.