Press Releases(Archive)

FASTECH 360 High-Speed Shinkansen Test Train to Debut

— Running Tests to Start with the Aim of the World's Best Shinkansen Service —

East Japan Railway Company

March 9, 2005

Two high-speed test trains are being built for this purpose, and one of these is to be ready in June 2005 for running tests, mainly between Sendai and Kitakami on the Tohoku Shinkansen.

JR East is manufacturing the two test trains. The eight-car E954 trainset has standard Shinkansen clearances, and is the one to be completed in June 2005. The E955 six-car trainset will meet clearance requirements for through-operation between standard Shinkansen and converted conventional lines, and is scheduled for completion in spring 2006.

- Technical Features of the Test Trains

Test train development has been based on the following three concepts.

- Prototype trains for operation at 360 km/h

- Experimental platforms for collecting information on effects when running at high speeds

- Design for improved comfort in near-future trains

The six intermediate cars of the E954 series train have motors. Technical features of the E954 series train are as follows.

[1] Faster running speeds - Development of compact and high output main circuit equipment (motors and propulsion components)

The test train performance will allow a maximum speed of 405 km/h, and the test train is equipped with three types of newly developed compact and high output main circuit equipment for comparison tests. - Improved high-speed current collection performance (performance that allows stable current collection from catenary even when running at high speeds)

The test train employs a newly developed pantograph with a multi-split slider, and the catenary facilities have also been improved to reduce the weight and increase the tension.

[2] Reliability assurance - Assuring safety in the event of earthquakes

The mechanism behind the derailment that occurred during the Niigata Chuetsu Earthquake is currently being investigated, and JR East is studying countermeasures that will reduce the chance of derailment, shorten the braking distance, and minimize the damage in the event of derailment.

For shortening the braking distance, brake performance has been greatly improved to allow trains to come to a swift stop in the event of an emergency, and tests will also be conducted using devices that increase air resistance, which are a first for railway cars. - Assuring reliability of running components

The test train bogies, bogie components and other running components are of new designs for high speeds, and highly reliable, low noise driving devices (the devices that transmit the motor rotation to the wheels) have also been newly developed.

Actual load endurance tests (600,000 km) for these vital components have already been completed using JR East's full-size bogie rotation test facility, and reliability will be further confirmed in the running tests. - Preventing snow hazards

The test train employs a structure that inhibits snow from sticking by modifying the car body shape around the bogies to improve the air flow and by using a heater to melt the snow.

[3] Eco-friendliness - Reduced noise

In addition to reducing the number of current collection pantographs per trainset from two to one pantograph, the newly developed low-noise pantograph and pantograph noise insulation panel help to reduce noise.

Steps have also been taken to smooth all parts of the car body such as completely covering the gap between the bogies and the car body. In addition, sound absorbing materials have been installed on the car body sides to reduce noise, which marks a first for the Shinkansen. - Reduced micro-pressure waves in tunnels

The E954 Series train has lengthened nose portions to reduce the micro-pressure waves in tunnels, and the cross-sectional area of the car body has been reduced as much as possible without compromising cabin comfort. In addition, the nose shapes have been aerodynamically optimized using computer simulations.

Two different types of nose shapes obtained by the simulations are located on the No. 1 and No. 8 cars for comparison tests.

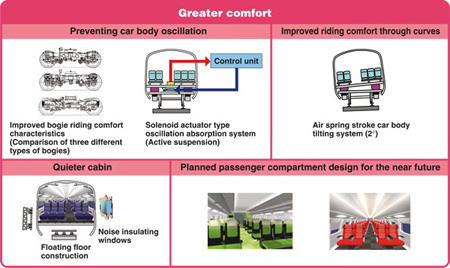

[4] Greater comfort - Improved riding comfort

In addition to improving the riding comfort characteristics of the bogies, tests will be conducted using a solenoid actuator type oscillation absorption system (active suspension) which is the first of its kind in Japan. - Quieter cabin

The car body incorporates noise insulating structures in the floors, windows, walls and other areas, and efforts are also being made to reduce the noise from running devices and electrical equipment. - Improved riding comfort through curves

The E954 Series train employs an air spring stroke car body tilting system to reduce the centrifugal force when passing through curves at high speeds, and tests will be conducted to confirm this performance. - Cabin design

The cabin design provides a comfortable passenger space for the near future that features new sanitary spaces, seats and an air conditioning system.

- High-Speed Test Train Names

The high-speed test trains are named as follows.

Standard clearance Shinkansen train (E954 Series): FASTECH 360 S

Conventional line through operation train (E955 Series): FASTECH 360 Z"FASTECH" is shortened from FASt TECHnology, "360" represents the target speed for technical development, "S" is the first letter of Shinkansen, and "Z" is the first letter of the Japanese word for conventional line (zairaisen).

- Exterior Design

[1] Nose shape The nose shape aims for the optimum aerodynamic shape, and the No. 1 and No. 8 cars use different designs for comparison.

No. 1 car: Stream-line (flowing like a stream)

No. 8 car: Arrow-line (sharp like an arrow)

[2] Coloring The upper half of the car body is green (JR East’s corporate logo color), the lower half is pearl white, and a silver metallic strip runs lengthwise below the windows. This coloring is based on the image of an advanced weather vane that glistens in a deep jade color while maintaining a transparent feeling. [3] Logo mark A logo mark that displays the name "FASTECH 360 S" in a decorative style is present on the test train car body.

Logo mark

Logo type

- The ring symbolizes the future.

- The pink dots are the numerous dreams entrusted to the high-speed test trains.

- The logo type expresses a sense of speed and sharpness, and the lower-case letters provide a feeling of familiarity.

- The logo mark includes the subtitle "The Frontier Spirit of JR East" which shows the pioneering spirit of JR East in its challenge to realize the world's best Shinkansen.

- Overview of High-Speed Running Tests

Following completion of the E954 Series train, running tests will be performed from June 2005 through fiscal year 2007 mainly between Sendai and Kitakami on the Tohoku Shinkansen. Running tests will be performed twice per week during the nighttime when service trains are not operated until sufficient results data are obtained to ascertain the running performance and environmental impact.

Except when increasing the speed to 405 km/h during the car body performance tests, in principle the maximum speed during the running tests will be between 275 km/h and 365 km/h.

Initially, running tests will be performed from June 2005 using only the E954 Series train. However, after the conventional line through operation train (E955 Series) is completed in spring 2006, passing tests, coupled running tests and other tests are scheduled using both trains.